As through-hole (PTH) assembly is being gradually replaced by surface mount technology (SMT) in many applications, which offers smaller form factors and higher assembly speeds, Bela remain committed to providing a leading PTH assembly service.

Our PTH assembly service are commonly used in electronic manufacturing for products that require high mechanical strength, durability, and reliability, such as industrial equipment, automotive electronics, and aerospace systems. They’re also used in cases where components with larger pin spacing or higher power requirements are used, as through-hole technology provides robust electrical connections that can handle higher currents and voltages.

Plated Through Holes (PTH) are a crucial feature in the design and assembly of printed circuit boards (PCBs).

These holes are drilled or milled through the substrate material and then plated with a conductive material, typically copper, to create a connection between the different layers of the board. By running traces between the plated through holes, components soldered in those positions are then electrically connected to other components on the circuit board.

The importance of PTH cannot be overstated as it allows for the creation of complex and interconnected circuits in a compact space. PTH also ensures that the electrical connections are secure and reliable, which is essential for the functioning of the PCB.

Plated Through Hole Assembly (PTHA) is the process of creating electrical connections between the different layers of a PCB by drilling or milling holes through the substrate material and then plating them with a conductive material, typically copper. PTHA involves running traces between the plated through holes to ensure that components soldered in those positions are electrically connected to other components on the circuit board.

The benefits of PTHA are numerous. For one, it allows for the creation of complex and interconnected circuits in a compact space. PTHA also ensures that the electrical connections are secure and reliable, which is essential for the functioning of the PCB.

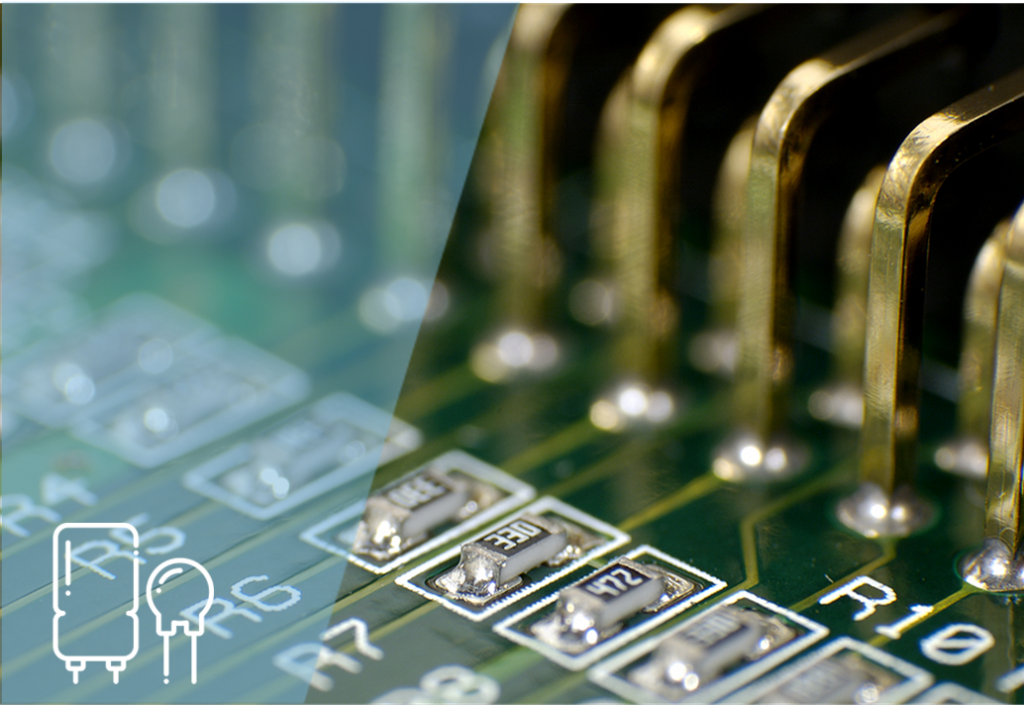

We use state-of-the-art equipment and industry-standard processes to carry out our plated through hole assembly services. Our team of experts ensures that each plated through hole is accurately drilled and plated to ensure reliable electrical connectivity. We also use advanced quality control measures to ensure that each PCB meets or exceeds the necessary standards. Our quality control measures include visual inspection, electrical testing, and X-ray inspection.

Plated Through Hole Assembly is an essential process in electronics manufacturing. PTHs are used to connect components on a PCB to ensure that the circuit functions as intended. Without PTHs, it would be challenging to create the complex and interconnected circuits required for modern electronic devices.

Moreover, the quality of PTHA is crucial for the reliability and longevity of the PCB. Poorly made PTHs can lead to electrical connectivity issues, which can cause the circuit to fail. This is especially important in high-stress environments where the PCB may be subjected to vibration, shock, or high temperatures.

Our through-hole facilities are driven by our Blakell LS 5000 light guided assembly workstations, offering maintained repeatability and accuracy.

All our operators are fully trained to program the machines via on-line programming.

We pay particular attention to minimising static damage. We use the Blundell Cropmatic for trimming component legs. We also design custom plates for delicate assemblies or highly populated PCBs.

Our Flow soldering is accomplished to IPC-A-610 Class 3 standard by fully trained operators using our lead free Blundell CMS 400 flow solder machine. Our CMS 400 is regularly serviced and calibrated by our trained and certified by Blundell. maintenance technicians.

Our dedicated hand assembly team enables us to offer a hand soldering process for both leaded and lead free solutions from single components to full board assembly.

All assembly benches are fitted with personal fume extraction systems and constant monitoring devices for static awareness.

We use industry-standard processes and advanced engineering equipment to ensure that each plated through hole is accurately drilled and plated. Our drill bits and endmills are made from tungsten-carbide, which is ideal for drilling small holes in the highly abrasive substrate of the PCB. We also have a rigorous quality control process in place to ensure that each PCB meets or exceeds the necessary standards that you and your customers expect.

Our process for PTH assembly involves several steps.

- First, the holes are drilled or milled through the substrate material.

- Next, the holes are cleaned and then plated with a conductive material.

- Finally, the holes are checked for accuracy and then tested for electrical connectivity