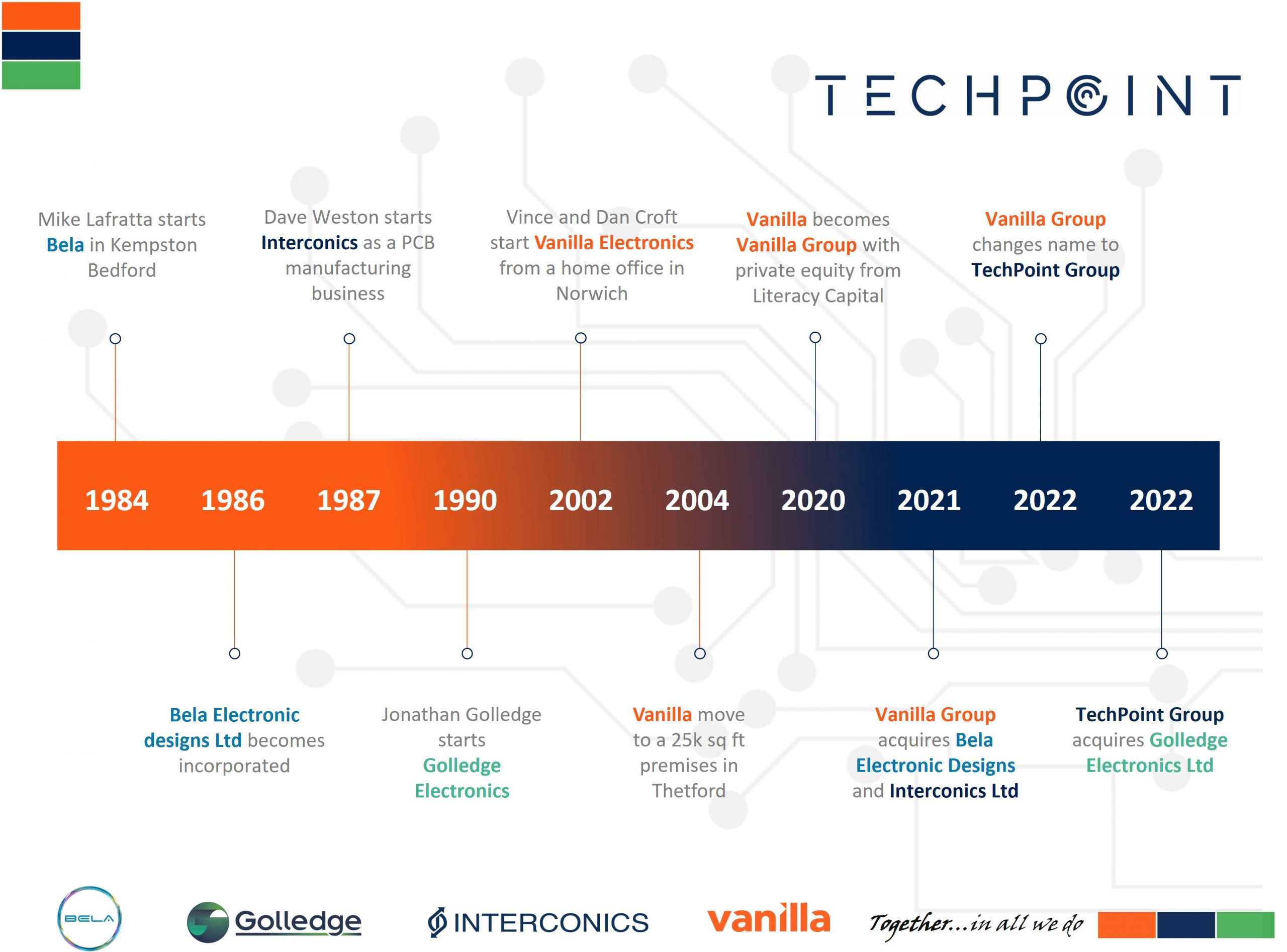

Bela Electronic Designs Ltd was conceived in 1984, when Mike Lafratta started up his Contract Electronic Manufacturing (CEM) business in Kempston, on the outskirts of Bedford. The business is very different today, yet retains the same heart and passion as when it was established, all those years ago. Bela continues to grow, to innovate and to lead.

Nowadays, Bela is regarded as the one of the market leaders in the small to medium volume high complexity manufacturing niche. It specialises in prototyping and new product innovation as well as PCB assembly. The business over many years has continued to work hard to develop its excellent reputation in the design and manufacture of printed circuit board assemblies (PCBAs) and has ensured that the business remains close to its core values, based on service and integrity.

March 2021 saw the business acquired by the then named ‘Vanilla Group’. The Vanilla Group has since been re-branded as ‘The TechPoint Group’.

Today Bela, and the TechPoint Group, continues to grow, continues to innovate and also continues to employ from the local community.

Excellence in manufacturing is not enough in the modern marketplace. What makes the difference is the level of service we provide and the integrity with which we conduct ourselves in our partnerships with our customers.