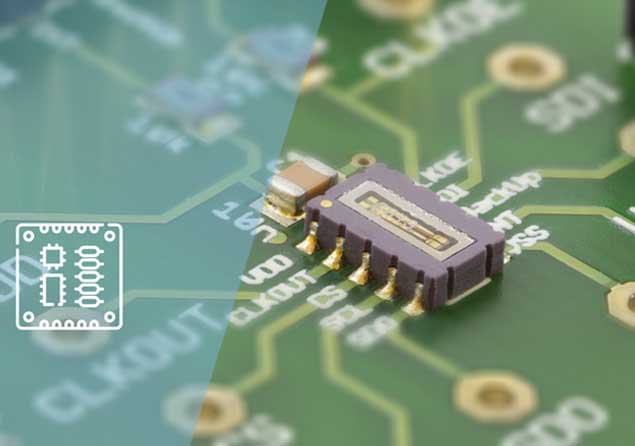

In the realm of electronics manufacturing, Surface Mount Technology (SMT) assembly plays a pivotal role. As a technique that mounts electronic components directly onto the surface of Printed Circuit Boards (PCBs), SMT assembly has become the backbone of modern electronics production and is a key component within the process of electronics manufacturing.

With the rise of complex electronic devices and miniaturisation trends, traditional through-hole assembly methods have become outpaced. SMT assembly is crucial in accommodating these technological advancements as it enables the production of high-density, multi-layer PCBs that are both lightweight and compact

The use of our SMT assembly offers a number of benefits to manufacturers

- Our Europlacer iineo’s allows circuit boards to be assembled very quickly. This reduces production times and generates cost savings

- Our SMT equipment is suited to complex and unique assembly requirements. It is highly bespoke and is enormously flexible

- Our state of the art kit allows for products with the smallest of dimensions to be used. Extremely small and sensitive components, such as crystals, resistors and diodes, can be mounted on circuit boards.

- SMT assembly lines also allows for greater control of the width of route traces, which helps reduce mechanical heat and noise, which improves the quality and performance of products

We regularly work on projects where we place components on both sides of a circuit board, either being pasted or soldered, removing the need to drill holes through the circuit board.

Our Europlacer iineo 1 machines offer extended feeder capacity of 240 positions per machine and a placement speed of 13,000 components per hour. These machines are ideal for prototypes, NPI, and small batch builds, as well as medium to high volume batch capability.

To complement our SMT Assembly line, we have a DEK Horizon 03i screen printer that enhances our process capability in the manufacture of all the latest SMT technologies by ensuring a precise and repeatable pasting process. Reflow is achieved using either convection or vapor phase processing techniques.

In 2016, we invested in the latest technology Ersa Hotflow 3/14e for reflow, which has a controlled 7 zone heat tunnel with a process length of over 4 meters. It has an adjustable bed width from 45mm up to 516mm, which allows us to process and reflow very large panels. The user interface is flexible in terms of settings and functionality, allowing the operator to set the most efficient settings across the reflow process.

For high complexity assemblies or where designs are thermally hungry, our Asscon VP800 Vapour Phase oven is deployed. Components are soldered in an inert atmosphere resulting in superior quality joints, and the added benefit of this technique being the properties of the chemistry involved (Galden) makes it impossible to thermally stress the assembly. Vapour Phase is also very quick to execute with minimal set-up, making it ideal for supporting small volume short lead-time requirements.

Surface Mount Technology (SMT) Assembly is the process of placing and soldering electronic components directly onto the surface of a printed circuit board (PCB). This is done using automated SMT machines that precisely place and solder the components onto the PCB.

Compared to traditional through-hole assembly, SMT Assembly offers several advantages.

Firstly, SMT components are much smaller and lighter than through-hole components, which means that PCBs can be designed to be much smaller and more compact. This is especially important for devices such as smartphones and wearables, where space is at a premium.

Secondly, SMT Assembly is much faster than traditional through-hole assembly. This is because automated machines can place and solder components much more quickly and accurately than manual methods. This makes SMT Assembly ideal for medium to high volume assembly requirements.

Finally, SMT Assembly also offers better electrical performance than traditional through-hole assembly. This is because the shorter connection lengths and smaller component sizes of SMT components result in lower inductance and capacitance, which in turn leads to better signal integrity and higher frequency response.

By choosing Bela Electronics for your SMT Assembly needs, you can enjoy a range of benefits that are designed to improve the quality and reliability of your electronic products.

Some of the key benefits of our SMT Assembly services include:

- High-quality and reliable electronic products

- Faster time-to-market

- Flexibility and scalability

- Cost-effective solutions

- Commitment to quality control

- Customer care and satisfaction

Quality control is critical for ensuring the reliability and performance of electronic products manufactured using SMT Assembly. At Bela Electronics, we understand the importance of quality control in SMT Assembly and have implemented strict measures to ensure that our products meet the highest standards of quality and reliability.

Our quality control measures begin at the design stage, where we work closely with our clients to ensure that their designs are optimised for SMT Assembly. We use advanced software and design tools to ensure that components are placed accurately and soldered correctly.

During the manufacturing process, we use automated optical inspection (AOI) to ensure that components are placed correctly and that there are no defects or issues with the solder joints. We also use x-ray inspection to check for hidden defects or issues that may not be visible to the naked eye.

In addition to these measures, we also conduct rigorous testing and analysis to ensure the reliability and performance of our products. We test our products under a range of conditions and use advanced equipment to measure their performance and identify any issues that may arise.